TECHNOLOGIES OF OUR PLANT

We have nothing to hide. Our plant is open for visitors. Every process is shown in many of our videos posted in socials. Our goal is everyone to have no doubt about the quality level of our production.

Technologies of Automatic Transmission repairing exist since the first AT was invented. More then 20 years passed since the first transmission repairing plants were founded. We’ve improved their processes with modern equipment to be up to the market demands.

CLEAN

We deal with used AT units. Wile being used their surfaces cover with dirt and oil.

Then the 1st step is to take all the dirt off next procedures to be produced with maximum possible cleanness.

We use industrial blaster to clean surfaces with metal shot.

DISASSEMBLE

We disassemble transmissions into more than a hundred parts. Valve body and torque converter are aside.

WASH

We use washing machines to clean all the parts from oil pollutions with special solvent.

It takes a few minutes to make the parts clean for comfortable use afterwards.

REVIEW AT PARTS

We review all the AT parts to check their condition. To find out what parts are good and it’s possible to re-use them in a new assenbly; what parts are not good enough but it’s possible to repair them for re-using after; what parts are completely defective and should be utilized.

REPAIR TORQUE CONVERTERS

We disassemble all the torque converters by cutting them in two pieces using turning lathe and taking all the parts off the body. Then all the same technology steps - washing, reviewing, repairing, assembling. All the steps are produced using modern TCRS specialized equipment.

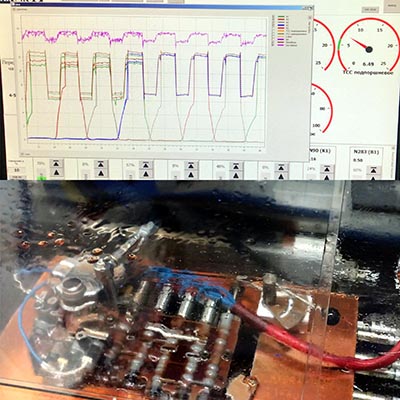

REPAIR VALVE BODIES

We use special testing equipment to check the difference between the used and a new one valve body of the same model. We use Sonnax tools and repair kits to restore all the working standards of a brand-new valve body.

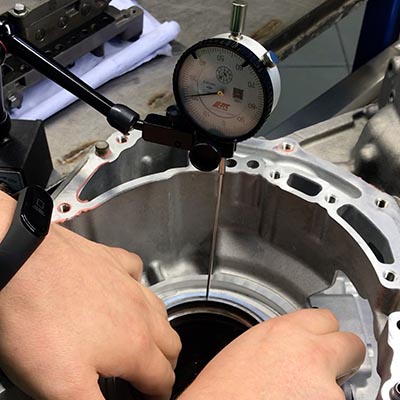

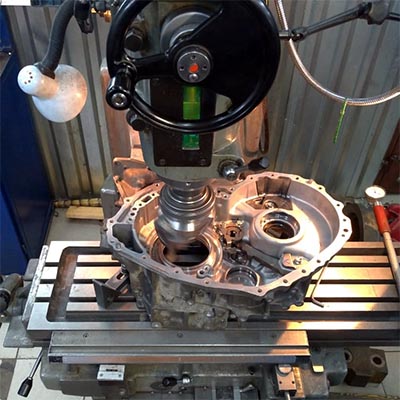

REPAIRE AT’S CASE

Some models of Automatic Transmissions have different problems with their cases. For some of them these problems are typical as, for example, for U660-U760 family of transmissions. We use milling machines with inserting new steel o-rings to solve problems.

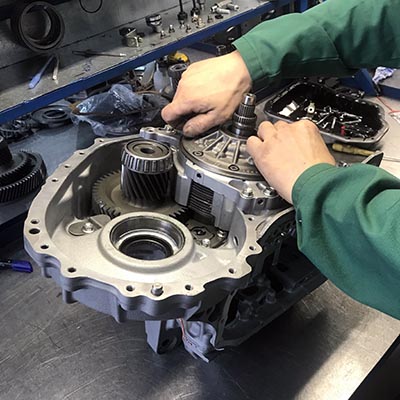

AT ASSEMBLY

We take some good used parts, some repaired and some brand-new parts to assemble new Automatic Transmission units. Our suppliers are official OEM parts manufacturers. All the transmission units have a few points to check for assembly correctness.

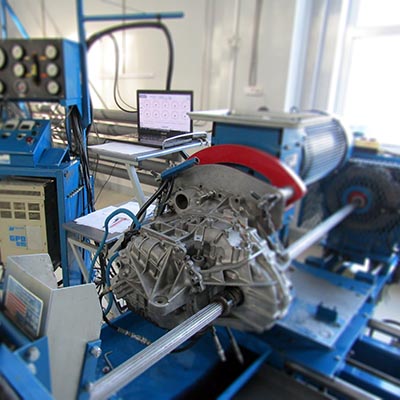

AT STAND TEST

All the Automatic Transmission units are finally checked on Superflow Axi-line stand. Transmission is tested with a special protocol in all the possible modes in cold and hot conditions of ATF.

If some parameters are not correct or out of acceptable range the transmission will be returned to step 2.

STORE

The only condition for rebuilt transmission to lie down the shelf of our store is all the steps (1-8) are passed and the final test (step 9) is good.

Every rebuilt AT is ready to supply with the order of our dealer/partner. We deal with delivery companies to send our transmissions to distant regions of our country and abroad.

When all the work is done we’ve got our product packed into a special delivery wood box. You place your order and we send the transmission to you straight away!